Ensuring Safety: Your Guide on Aerial Rigging Hardware Strength Testing and Certification.

Votre équipement, testé.

Les arts aériens sont exaltants, stimulants, mais vraiment fascinants. C'est votre expression personnelle libérée de la manière la plus rafraîchissante et la plus authentique, inspirant tous ceux qui lèvent les yeux.

Pour avoir l'esprit tranquille et perfectionner votre art comme vous le souhaitez, vous avez besoin d'un équipement fiable, sûr et solide. Nous y parvenons en testant la résistance de chaque lot d'équipement Orbsoul fabriqué.

Qu’est-ce que le test de rupture de lot ?

Les tests de rupture de lots impliquent de tester des échantillons de chaque lot produit pour déterminer leur résistance minimale à la rupture (MBS) . Ces tests sont importants pour garantir la sécurité et la fiabilité de l’équipement de gréage utilisé dans les arts et spectacles aériens.

Lors des tests de rupture de lots, un échantillon des composants du gréement du lot est soumis à une tension contrôlée jusqu'à ce qu'il se déforme (casse) pour la première fois. La résistance à la rupture de chaque composant est enregistrée et les résultats sont utilisés pour déterminer si le lot répond aux normes de sécurité requises.

Les tests de rupture par lots permettent d'identifier les faiblesses ou les défauts des composants du gréement qui pourraient entraîner une défaillance pendant l'utilisation. En testant un échantillon de chaque lot, nous pouvons garantir que tous les lots d'équipement de gréage produits peuvent être utilisés sans danger pour les aviateurs.

Comment la résistance minimale à la rupture (MBS) est-elle déterminée ?

Les tests de résistance mécanique à la traction sont un processus crucial utilisé pour déterminer la charge maximale qu'un matériau ou une structure peut supporter avant de se déformer ou de se briser. Il s'agit de soumettre un échantillon d'un composant à une tension progressivement croissante jusqu'à ce qu'il atteigne une déformation (point de rupture) . Cette méthode de test fournit des données précieuses sur la durabilité et la résilience du matériau et documente la MBS (résistance minimale à la rupture).

Pourquoi avons-nous besoin de cela ?

- Assurance sécurité : Les soieries aériennes et le matériel de gréement sont soumis à des tensions et des contraintes considérables lors des performances ou des séances d'entraînement. S'assurer que ces matériaux et composants peuvent résister aux charges attendues sans défaillance est primordial pour garantir la sécurité des voltigeurs et des artistes.

- Optimisation des performances : En connaissant la résistance mécanique à la traction des soies aériennes et du matériel de gréement, nous pouvons concevoir des produits qui respectent ou dépassent les normes de sécurité requises tout en optimisant les performances. Comprendre les limites des matériaux permet de développer des équipements capables de résister à une utilisation rigoureuse et à des manœuvres exigeantes sans compromettre la sécurité.

- Contrôle qualité : les tests de résistance mécanique à la traction servent de mesure de contrôle qualité pour les soies aériennes et le matériel de gréement. Chez Orbsoul, en testant des échantillons de chaque lot de production, nous garantissons la cohérence, la résistance et la fiabilité continues de nos produits. L'identification précoce des faiblesses ou des variations des matériaux permet d'éviter d'éventuels accidents ou pannes lors d'une utilisation réelle.

- Conformité réglementaire : Dans de nombreuses juridictions, il existe des réglementations et des normes spécifiques régissant la conception et la fabrication des équipements utilisés dans les arts et spectacles aériens. Les essais de résistance mécanique à la traction fournissent des données empiriques qui peuvent être utilisées pour démontrer la conformité à ces normes, garantissant ainsi le respect des obligations légales et réglementaires.

- Atténuation des risques : une compréhension approfondie des propriétés mécaniques du matériel de gréage permet une évaluation éclairée des risques et des stratégies d'atténuation. En identifiant les points de défaillance ou les points faibles potentiels, des mesures peuvent être prises pour renforcer ou repenser l'équipement afin de minimiser le risque d'accidents ou de blessures lors des performances aériennes.

Comprendre le test et les résultats

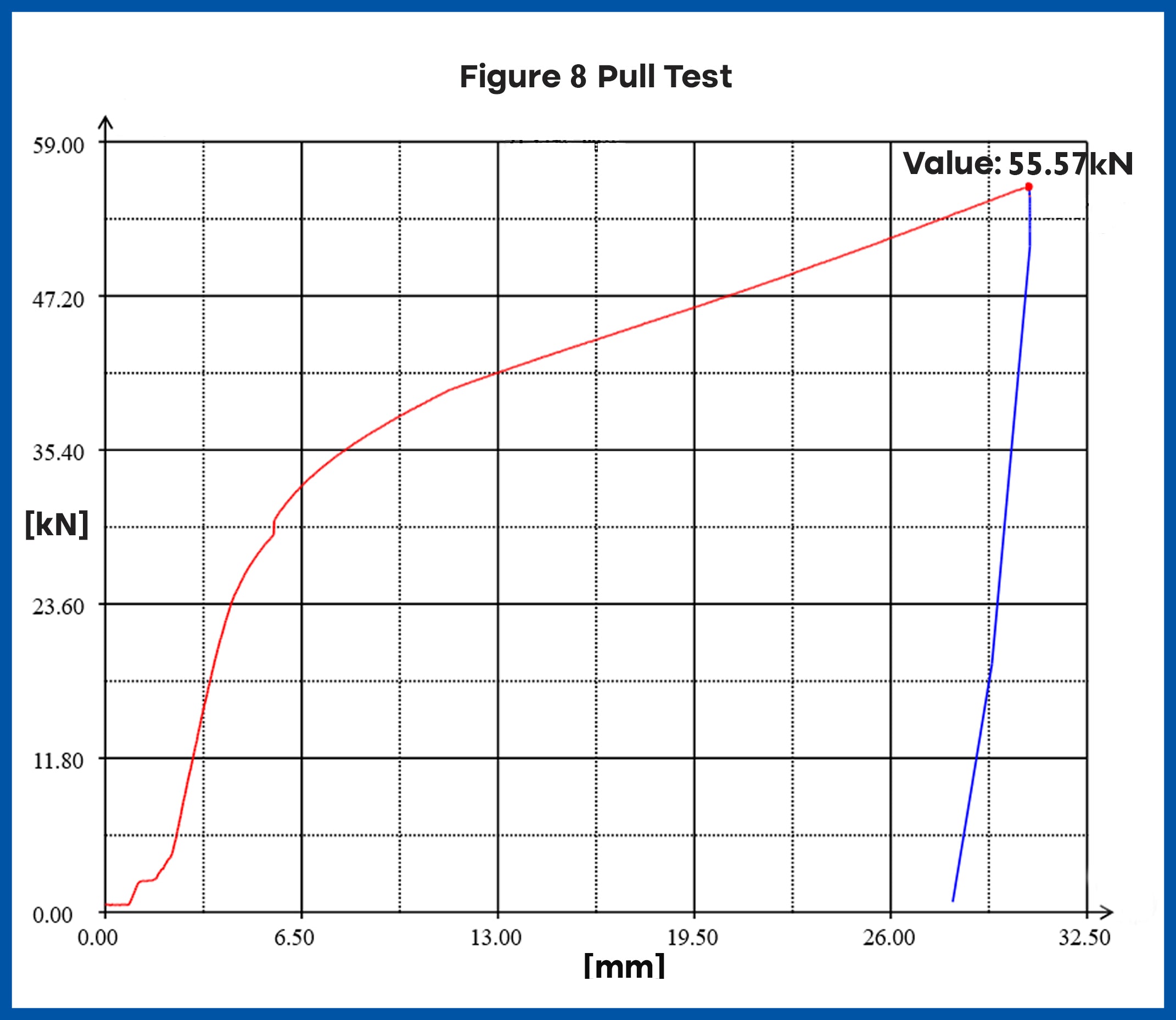

Un graphique d'essai de traction illustre la relation entre la force appliquée (contrainte) et la déformation (déformation) résultante d'un matériau. Généralement, cela commence par une région linéaire où la contrainte et la déformation augmentent proportionnellement, appelée région élastique. Au-delà de cela, le graphique présente une déformation plastique, où le matériau subit des changements permanents mais peut encore revenir dans une certaine mesure à sa forme originale. Enfin, il atteint un point de résistance ultime à la traction, représentant la force maximale que le matériau peut supporter avant de se briser. Le point auquel le sujet de test entre dans l’étape de déformation plastique est appelé limite d’élasticité ou limite d’élasticité. Cette valeur (mesurée en kN) correspond à la valeur nominale de votre équipement et est marquée sur chaque élément de matériel.

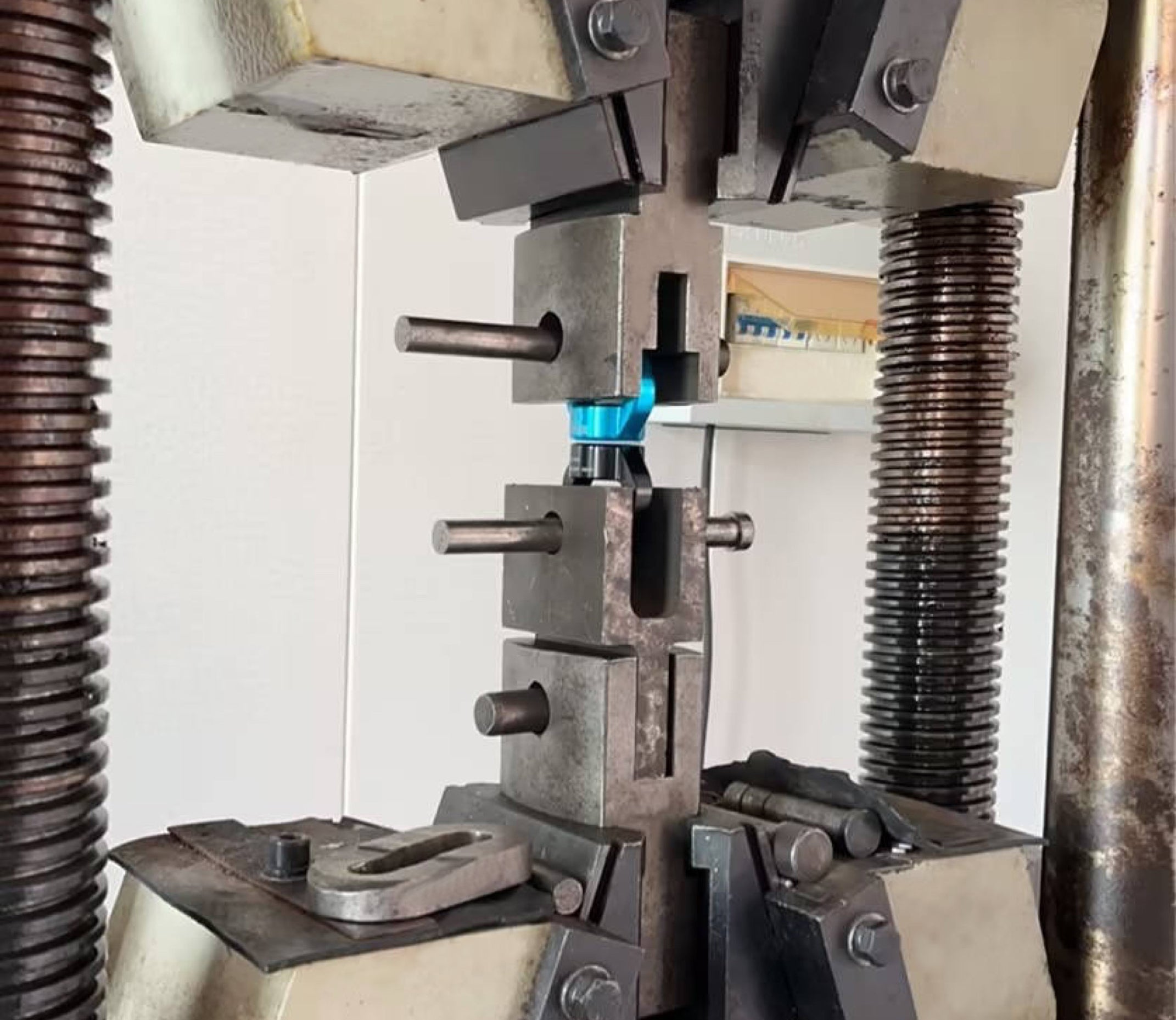

Entrez dans le laboratoire.

Voici les performances de votre équipement lors de son récent test par lots.

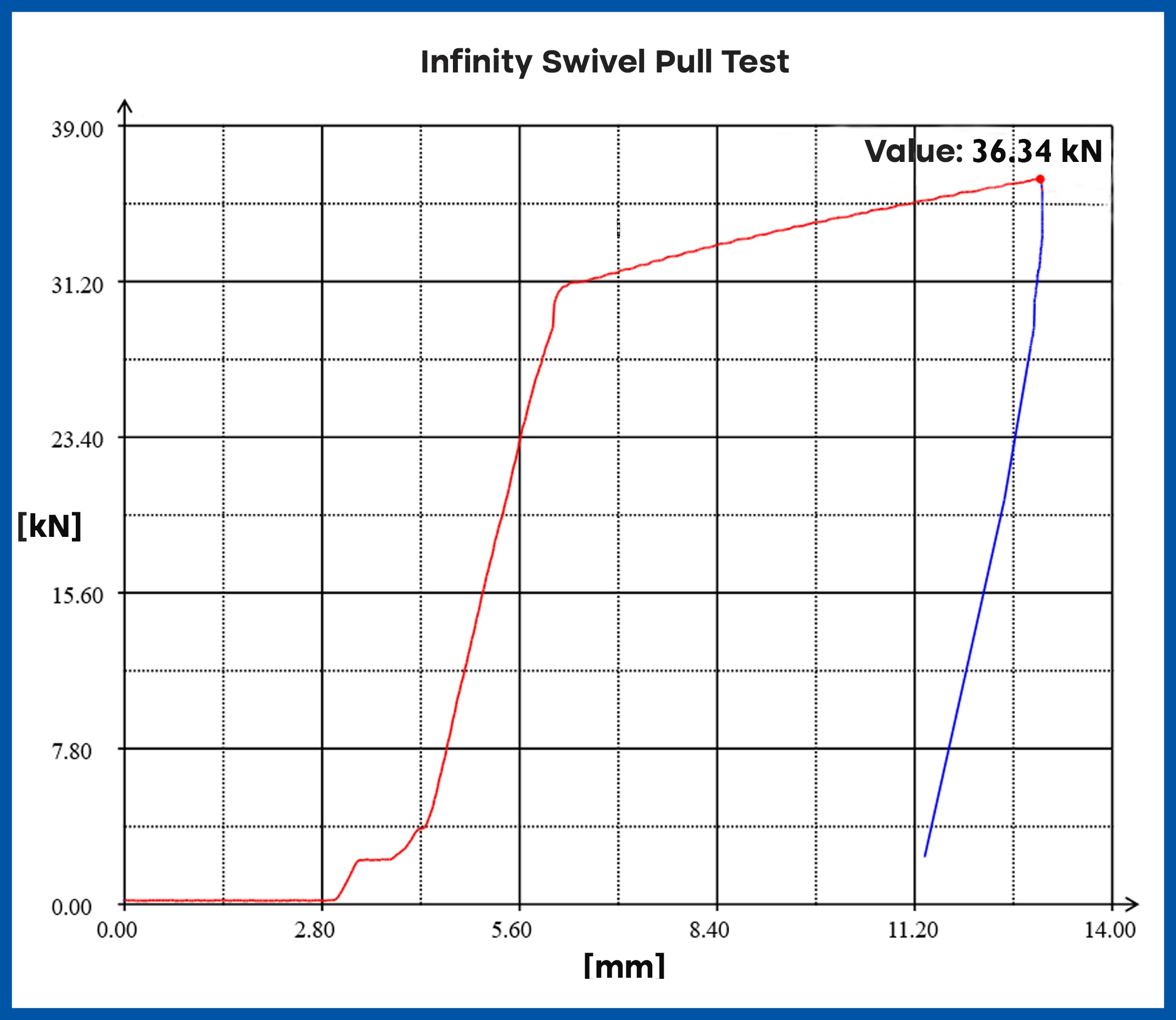

Test de résistance à la traction pivotant à l'infini

L'émerillon infini présente une résistance à la traction ultime de 36 kN. Cependant, nous établissons la résistance nominale de l'émerillon à 30 kN, car cela correspond à sa limite d'élasticité.

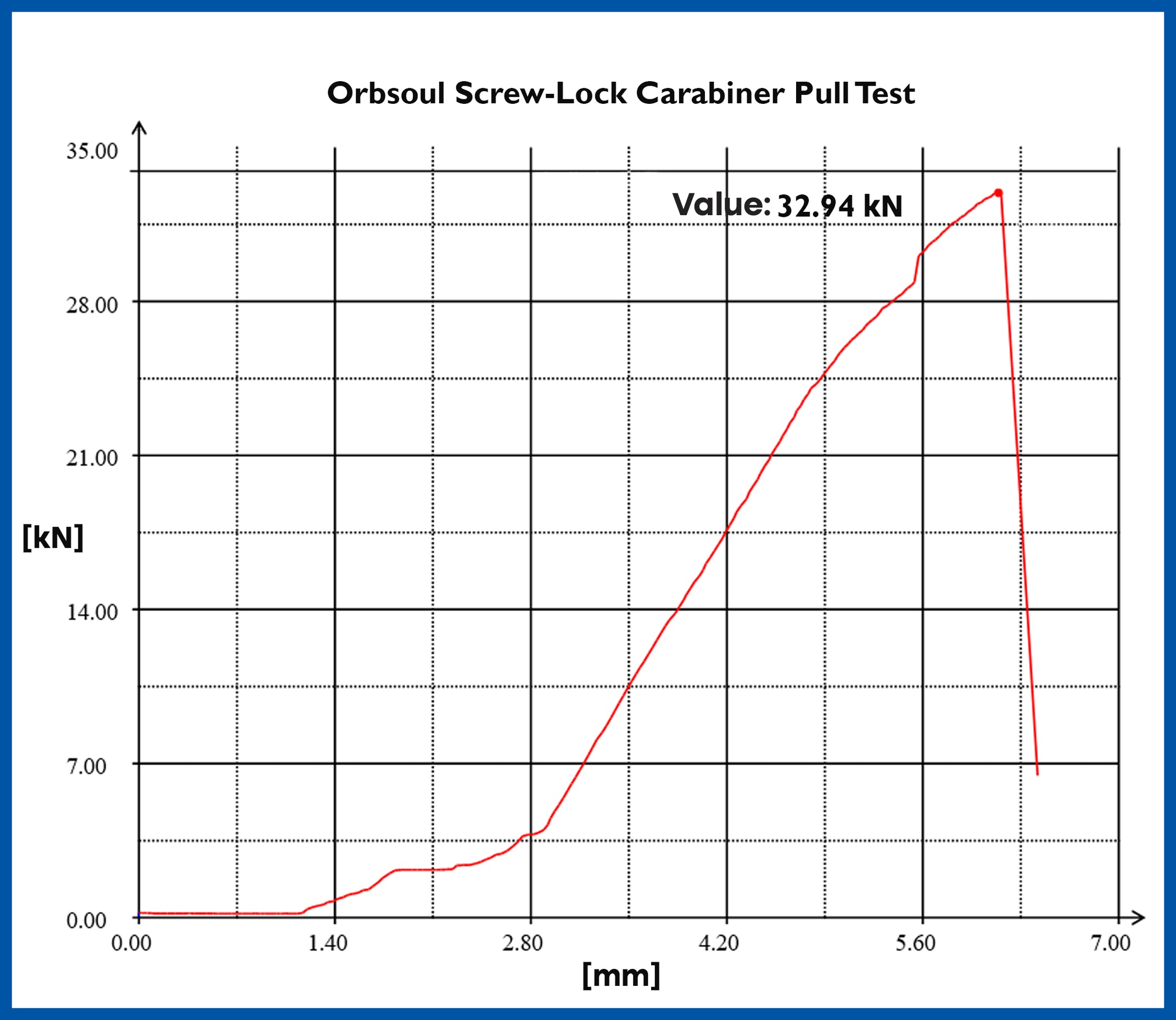

Test de résistance des mousquetons à vis

Le mousqueton à vis présente une résistance à la traction ultime de 32 kN. Cependant, nous établissons la résistance nominale à 25 kN, car cela correspond à sa limite d'élasticité.

Figure 8 Test de résistance à la traction du descendeur

Le Descendeur Figure Eight présente une résistance à la traction ultime de 55 kN. Cependant, nous établissons la résistance nominale à 50 kN, car cela correspond à sa limite d'élasticité.

FREE SHIPPING OVER 50$ & FREE RETURNS.

FREE SHIPPING OVER 50$ & FREE RETURNS.

YOUR GEAR, FULLY WARRANTED.

YOUR GEAR, FULLY WARRANTED.